Introduction

While I was struggling to resume work on my Bachem Natter, I got distracted by a program I installed a year ago --

Autodesk's 123D Make. 123D Make is a neat application that processes a 3D model by slicing it into many layers of uniform thickness. The resulting pattern is then generated which will allow you to reconstruct the model.

By default, the target medium is corrugated cardboard which is then cut using a laser cutter.

Unfortunately, I don't have a laser cutter. This is probably why the program sat on my HDD for such a long time. Then, I realized that it was possible to change the settings of the application to a different target medium. I have a stack of 190GSM card stock which is approximately 1/3mm thick. I decided to give 123D a try.

I chose a model that has a good mix of curved and straight surfaces. I picked the ME-328.

Creating the Modeling in Metaseq

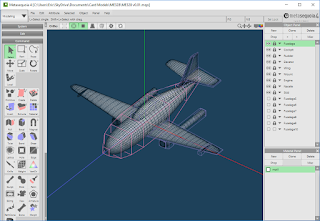

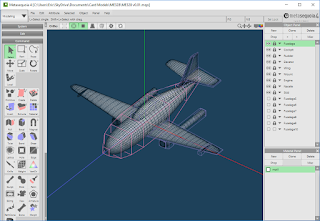

So I fired up Metaseq and quickly whipped up a low poly model:

I made sure not to go overboard with the details. Once satisfied, I converted the low poly model into the standard mesh:

Slicing it up in 123D Make!

Fortunately, Metaseq is able to export to OBJ format. This allowed me to import the OBJ model into 123D Make.

Here's how it looks like under 123D Make:

After setting the target medium to 0.33mm thick A4 sheets, 123D Make started to sliced up the model. Here's how it looks like:

Since I didn't want to use a lot of paper, I adjusted the target size of the model just enough to generate parts that would use 2 A4 sheets. I then saved the plans to PDF for printing:

Building the Model

I thought.. I really thought I could finish cutting and building these parts within a day. But I was wrong.

I end this blog entry with pictures of the work in progress.

I'll continue my build next weekend.

つづく